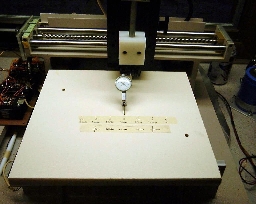

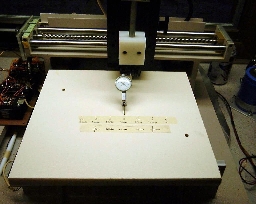

The X-Axis

A dial indicator is moved left and right and the readings are marked on tape. |

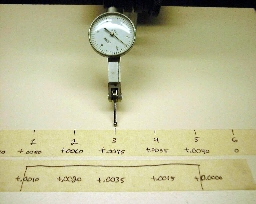

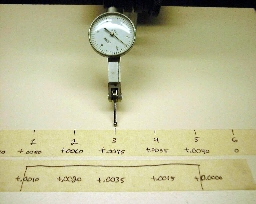

Closeup. |

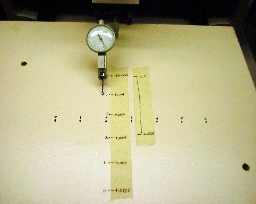

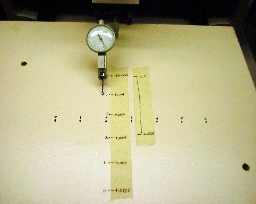

The Y-Axis

A dial indicator is moved forward and backwards and the readings are marked on tape. |

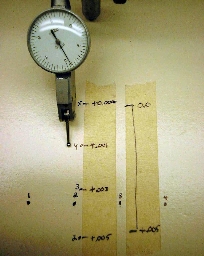

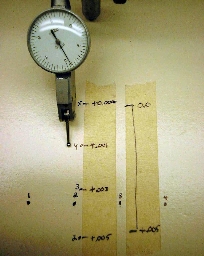

Closeup. |

This page created 06-13-2001

I have been working on Jeff Sampson's mill to see if we can figure out

how to mill PCB traces.

Here I have replaced the original plywood board with a piece of particle board

shelf material which is much more flat.

I know I should use something like 1/4 Inch aluminum, but this was handy.

So, how flat is it? I mounted a dial indicator onto the Z-Axis mount, and

drove it around a bit.

The smaller pieces of tape represent the board example I am trying, so I can

tell how flat the table is over that distance.

As you can see, the board will move up towards the cutter 0.0035 Inches in the middle. How much will this change the width of a cut?

If the bit is at a 45 degree angle the cut will get 0.0028 Inches wider.

This seems fine since we will be cutting traces at a minimum of 0.02 inches wide.

So, It's on to more measurements, and then trying to mill.

Oh by the way, the smallest X or Y step we can make is 0.00125 Inches, so I think

we'll be OK there also.

We'll see.......

Click thumbnails for a larger view.

A dial indicator is moved left and right and the readings are marked on tape. |

Closeup. |

A dial indicator is moved forward and backwards and the readings are marked on tape. |

Closeup. |